GRIMME

THE RECEIVING HOPPERS OF THE RH SERIES GET NEW UPGRADES

The GRIMME receiving hoppers of RH- and RH-Combi series have been updated with various new features.

Storing according to tuber size

In order to grade different sizes of potatoes and onions during storage and processing , web graders are used. Optionally, the new web grader, type WG 900, can be permanently integrated into the receiving hoppers RH 12 Combi, RH 20 Combi and RH 24 Combi. This new combination of two coordinated machines makes it possible to combine crop intake, soil cleaning, picking, sorting and dividing the crop into two different sizes with just one machine. And all this with an optimal, straight-aligned crop flow.

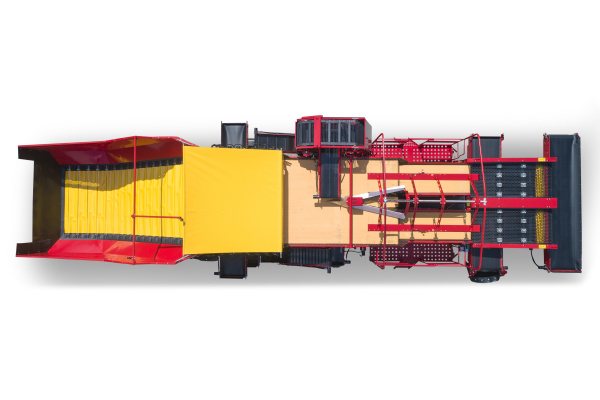

Picture: Receiving hopper, type RH 12-60 Combi with an integrated web grader WG 900.

Picture: The result is an optimised, straight crop flow without bottle neck.

Merging conveyor belt for all impurities and trash.

For an improved, flexible use of the receiving hoppers RH 20 and

RH 24, the PU-rollers of the pre-grading unit can be used in heavy, sticky soil conditions not only for tuber grading but also for cleaning off adhering soil. An optionally integrated merging conveyor transfers the trash, which is separated by the rollers of the pregrading unit, onto the soil cross conveyor. The advantage is that merged amounts of trash are discharged all at once onto a single downstream following conveyor. If the pre-grading unit is only to be used for pre-grading (fractioning), then the pre-grading cross conveyor can simply be pushed back over collecting conveyor belt. The collecting conveyor belt is mounted within the width of the machine and is better protected against collisions during manoeuvring.

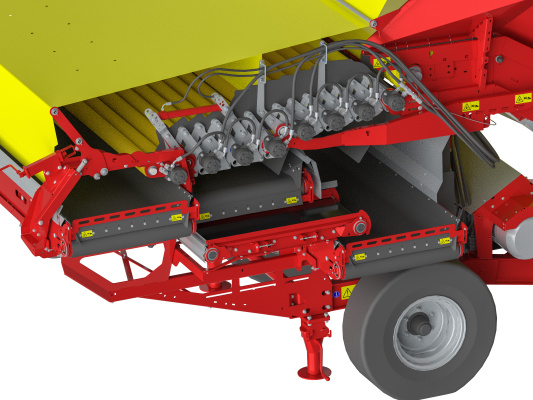

Picture: The collecting conveyor belt to merge the products of the pregrading cross conveyor and the soil cross conveyor.

Working lights

Six LED working lights are optionally available for the receiving hoppers type RH 20 and RH 24 to illuminate the machine and its surrounding. The working lights can be individually aligned or repositioned.

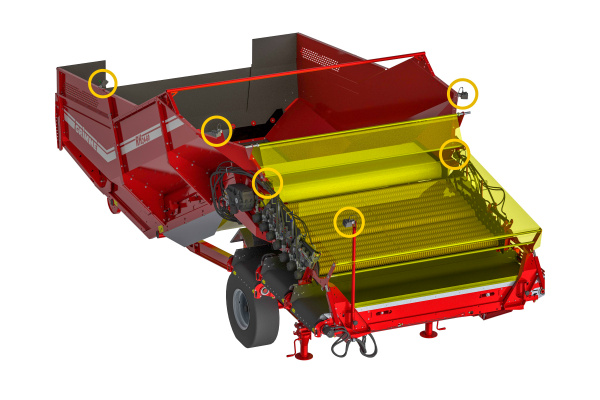

Picture: Six LED working lights enable a perfect illumination of the machine and its surrounding.

Protective casing for the operator terminal

For a dust-free and waterproof storage of the operator terminal and other operating devices, such as a remote control for the store loader, all GRIMME receiving hoppers can now be equipped with a protective casing.

Picture: Protect the operator terminal reliably against dust and moisture.

Innovation

Whether its new machines or digital solutions, you'll find all the latest information here.

Display all updates