EVO 280

THE EVOLUTION OF THE SE SERIES

GRIMME presented the two-row potato harvester EVO 290 with a 9 tons bunker and two separators as well as the AirSep as an option at 2017 Agritechnica.

GRIMME presented the two-row potato harvester EVO 290 with a 9 tons bunker and two separators as well as the AirSep as an option at 2017 Agritechnica. At the GRIMME Technica the EVO 280 with 8 tons bunker and 3 separators was presented internationally for the first time.

With the new 2 row trailed harvester EVO 280 the market needs for enhanced harvesting capacity and soil conservation have been met, allowing greater levels of performance, incorporating technology from the highly successful SE 150-60. The bunker volume could be increased by 33 %, the sieving area is significantly higher and the performance of the separators has improved. With the integrated gantry axle, a road transport width of 3 meters ha been achieved. The new design also catches the eye and is based on the EVO 290.

Double plus: Increased performance and improved gentle crop handling

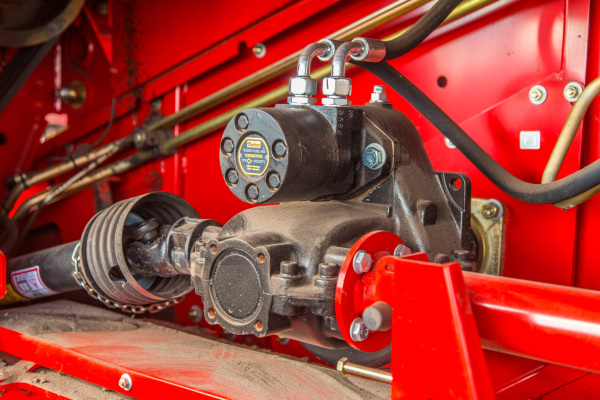

The pulled intake is particularly easy to pull and can optionally be equipped with TerraControl for a constant digging depth under all harvesting conditions. Thus avoids unnecessary compactions of the ridges. The TerraDisc disc coulter intake is available for heavy soils, without diablo rollers. The first main web has a 16 % higher sieving area. An intake web for heavy conditions is available as an option. The main webs can be equipped with the patented, infinitely adjustable and reversible VarioDrive. The drop heights between the main webs and onto the first separator have been reduced again. The first separator is 15 % and the second separator is 78 % wider. This ensures another significant increase of performance. The third separator is either the clod separator ClodSep or for lighter conditions the EasySep. The optional Speedtronic automatically adjusts the speed of the separators and the picking table to the harvesting conditions, thus increasing crop protection while at the same time increasing area output and relieving the strain on the driver. The ergonomically designed picking platform has space for 6 instead of 4 pickers at the horizontal and 1100 mm wide picking table.

The 8-tons bunker

The EVO 280 with the 8 tons bunker belongs to the largest trailed potato harvester. The capacity has increased by 33 % in comparison to the SE 150-60 standard bunker. This results in a noticeably smaller number of so called "multiple overrunning" of wheels when the bunker is full. The automatic bunker filling incl. the automatic for the final elevator are standard, the bunker head lowering is available as an option.

3 meter transport width and safe digging

The EVO 280 is powerful but still compact in design to realize a transport width of 3 meter. The up to 3.5 meter telescopic axle ensures exceptional stability of the harvester even when the bunker is full. The optionally available 850/50 R30.5 radial tyres allow a ground compaction protection. Automatic levelling and axle self-centring are standard equipment.

The ISOBUS capable EVO 280 is either controlled via the CCI 50 or the new 12.1 inch CCI 1200 terminal. Thanks to MemoryControl, the favoured parameters can be stored and conveniently recalled. That reduces setting times especially when changing the driver or field. With the Visual Protect video system, the driver has everything in view at all times and is automatically alerted to potentially critical conditions via image switching. A connection to the customer portal myGRIMME is possible by means of a standard telematics unit, so that the user can conveniently call up all machine parameters from the PC, tablet or mobile phone.

The EVO 280 is another high performance 2-row bunker harvester alongside the EVO 290, the EVO 290 AirSep, the SE 260, the SV 260 and the SE 150-60 that can be used for potatoes, carrots and onions, among other root crop.

Innovation

Whether its new machines or digital solutions, you'll find all the latest information here.

Display all updates